Self-clinching nuts are specialized fasteners designed to create strong, permanent threaded connections in thin sheet metal applications. Their production requires precision and multiple manufacturing stages to ensure durability, strength, and reliable performance. Below is a detailed overview of the entire production process, from material selection to final quality control, that goes into manufacturing high-quality self-clinching nuts.

1. Material Selection and Preparation

The process begins with selecting the appropriate material, depending on the required characteristics of the self-clinching nut. Common materials include:

· Carbon Steel: Offers strength and durability, often treated to resist corrosion.

· Stainless Steel: Provides excellent corrosion resistance for harsh environments.

· Aluminum: Lightweight and corrosion-resistant, useful where weight savings are critical.

· Brass: Known for its corrosion resistance and conductivity, suitable for electronic applications.

Once selected, the material is cut into manageable pieces or sheets, preparing it for further processing. Material selection is critical because it dictates the mechanical properties and long-term performance of the self-clinching nut.

2. Forming the Basic Shape

The next stage involves shaping the material into the form of a nut. This is typically done through cold forging or stamping, depending on the production scale and material type.

·

Cold Forging: In this method, high pressure is applied to shape the metal at room temperature. This results in increased strength and durability by aligning the metal’s grain structure.

·

Stamping: Stamping involves pressing the material into a specific shape using a high-speed punch press. This process can handle high volumes quickly and is widely used for large-scale production of self-clinching nuts.

·

The result is a blank piece with the rough outline of a nut, without the internal threads or any surface treatments.

3. Machining and Threading

After the basic shape is formed, the next step is to machine the blank piece and create the internal threads, allowing the nut to receive a screw or bolt. Thread tapping is commonly used to create the internal threads, ensuring precise alignment and uniformity.

In some cases, the threads may be pre-formed during cold forging, but secondary machining often adds further precision, especially for fine-pitch threads. Threading is a highly controlled process, as it directly affects the fit and function of the self-clinching nut in applications.

4. Heat Treatment

Heat treatment is a crucial step for self-clinching nuts made of materials like carbon steel, where additional strength, hardness, and durability are desired. Heat treatment methods commonly applied include:

·

Annealing: This process reduces internal stresses and improves ductility, making the nut more resistant to cracking during installation.

·

Quenching and Tempering: The nuts are heated to a high temperature and then rapidly cooled (quenching), followed by reheating to a lower temperature (tempering). This process enhances both hardness and toughness, particularly beneficial for nuts that need to withstand high loads.

·

The specific heat treatment process varies based on the material properties required for the final application. Proper heat treatment also minimizes the risk of deformation during installation.

5. Surface Treatment

Once heat-treated, self-clinching nuts undergo surface treatments to protect against corrosion and wear, improving both their appearance and longevity. Common surface treatments include:

·

Zinc Plating: This treatment is common for steel nuts and provides a corrosion-resistant layer that protects against moisture, extending the nut's lifespan.

·

Anodizing: Used mainly for aluminum nuts, anodizing thickens the natural oxide layer on the surface, improving resistance to corrosion and enhancing surface hardness.

·

Black Oxide: This method adds a mild corrosion-resistant coating with a matte black finish, commonly used in automotive and electronics applications.

·

Nickel or Chrome Plating: These add an attractive and highly durable layer, improving both aesthetics and corrosion resistance.

·

The type of surface treatment applied depends on the intended application environment, with harsher environments requiring more robust coatings.

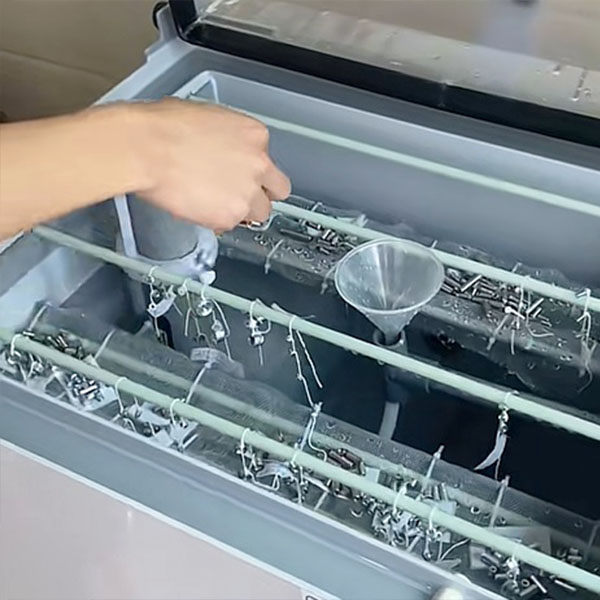

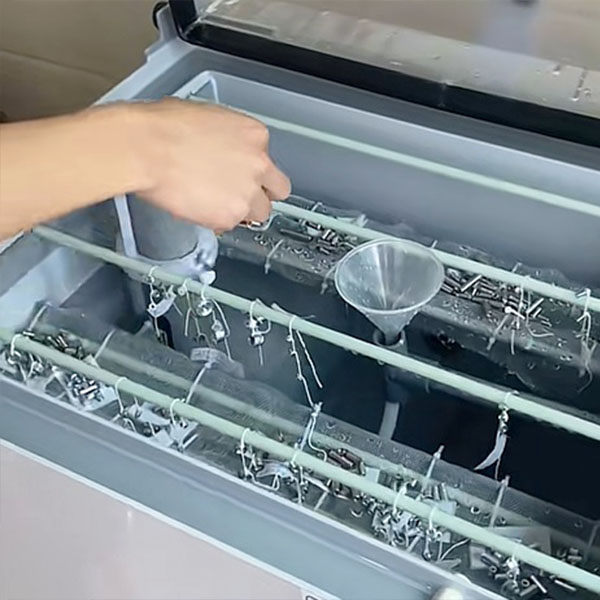

6. Inspection and Quality Control

Quality control is essential to ensure that self-clinching nuts meet all required specifications for dimensions, strength, and corrosion resistance. Typical inspection and testing methods include:

·

Dimensional Checks: Using micrometers and calipers, the dimensions of each batch are verified against design specifications to ensure uniformity.

·

Thread Integrity Testing: Thread gauges are used to check the fit of the threads, ensuring that they match the required screw or bolt specifications.

·

Hardness Testing: For heat-treated nuts, hardness tests (e.g., Rockwell hardness tests) confirm that the material meets the strength and durability requirements.

·

Corrosion Resistance Testing: Salt spray testing or other corrosion resistance tests may be performed to ensure the surface treatment provides adequate protection.

·

Any product that does not meet the specifications is removed from the production line to maintain quality standards.

7. Packaging and Distribution

Once inspected, the self-clinching nuts are cleaned to remove any residual oils or metal shavings and are then packaged. The packaging often includes labeling with essential information, such as material type, size, and batch number. This ensures that distributors and end-users can easily identify and select the appropriate nut for their needs.

Packaging may vary depending on the customer’s requirements, with options for bulk packaging or smaller, individual packages. Once packaged, the nuts are distributed to suppliers or directly to customers.

Final Considerations

Self-clinching nuts undergo a meticulous production process to ensure durability, precise dimensions, and reliable performance. With each stage of production carefully controlled, these fasteners are prepared to meet the rigorous demands of various industries, including automotive, electronics, aerospace, and consumer goods.

Summary of Production Process for Self-Clinching Nuts

1. Material Selection and Preparation

2. Forming the Basic Shape

3. Machining and Threading

4. Heat Treatment

5. Surface Treatment

6. Inspection and Quality Control

7. Packaging and Distribution

By understanding the comprehensive production process, manufacturers and buyers alike can appreciate the quality and performance that self-clinching nuts provide, ensuring a secure, durable fastening solution for diverse applications.