Clinch studs, also known as self-clinching studs or press-fit studs, are specialized fasteners designed to provide permanent threaded attachments in thin metal sheets or panels. Their unique structure and installation method make them indispensable in industries requiring reliable, vibration-resistant connections. This article explores the material composition, design features, working principles, and practical applications of clinch studs, along with step-by-step installation guidelines.

1. Material Composition

Clinch studs are typically manufactured from high-strength materials to withstand mechanical stress and environmental factors. Common materials include:

Stainless Steel (e.g., SS304, SS316): Offers corrosion resistance and durability for harsh environments.

Carbon Steel: Often zinc-plated for improved rust resistance and cost-effectiveness.

Aluminum: Lightweight and ideal for applications requiring reduced weight.

2. Structural Features

Clinch studs are engineered with precision to ensure secure fastening:

Head Design: A knurled or serrated head provides anti-rotation properties during installation.

Threaded Shank: Standard metric or imperial threads (e.g., M4, M6, 1/4"-20) for compatibility with nuts or mating components.

Clinch Ring/Flange: A circular groove or raised collar beneath the head that deforms into the host material during installation, creating a permanent lock.

3. Surface Treatments

Surface coatings enhance performance and longevity:

Zinc Plating: Common for corrosion protection in carbon steel studs.

Nickel Plating: Improves wear resistance and aesthetics.

Phosphate Coating: Enhances adhesion for subsequent painting or powder coating.

Passivation (for stainless steel): Removes free iron particles to maximize corrosion resistance.

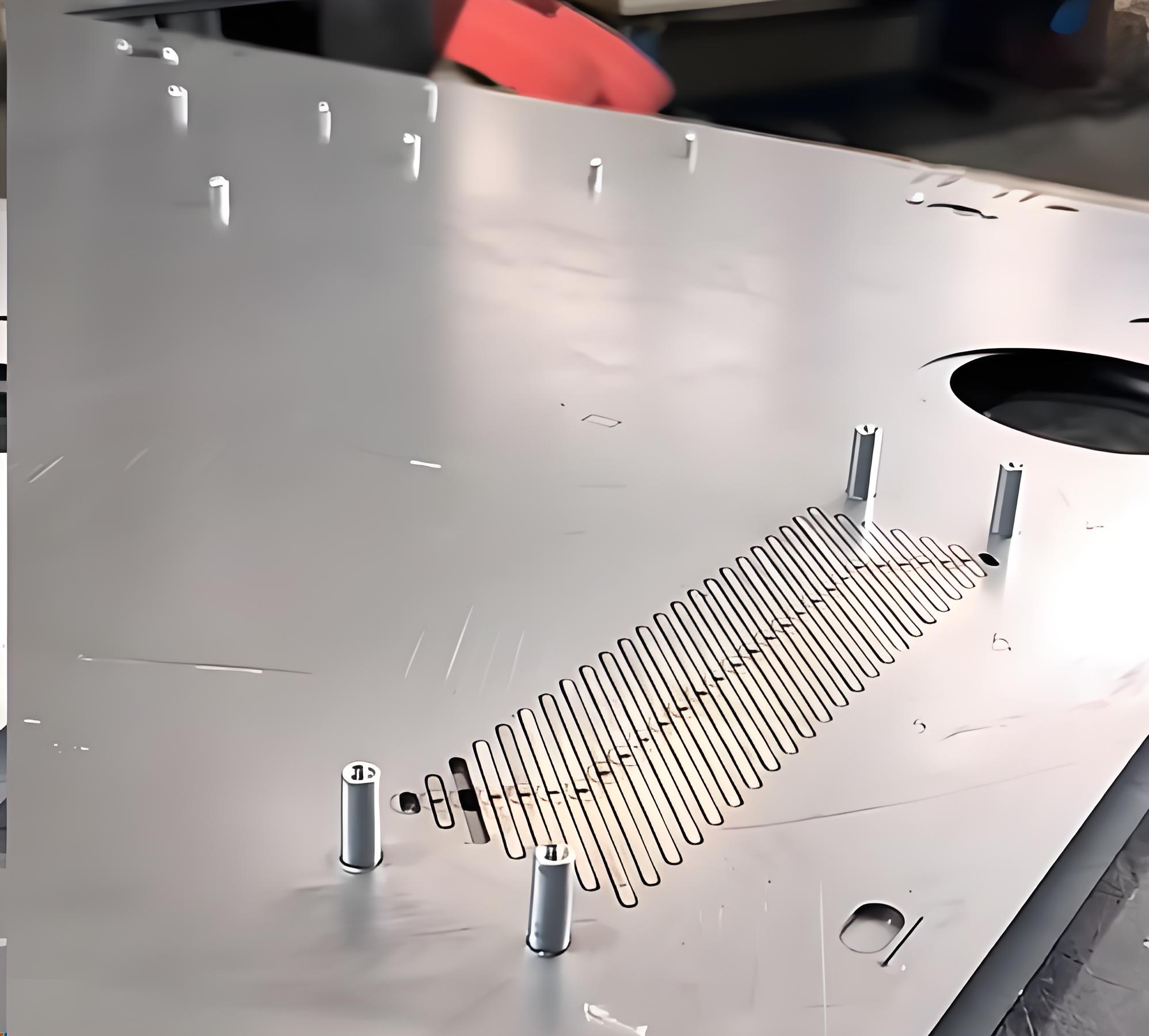

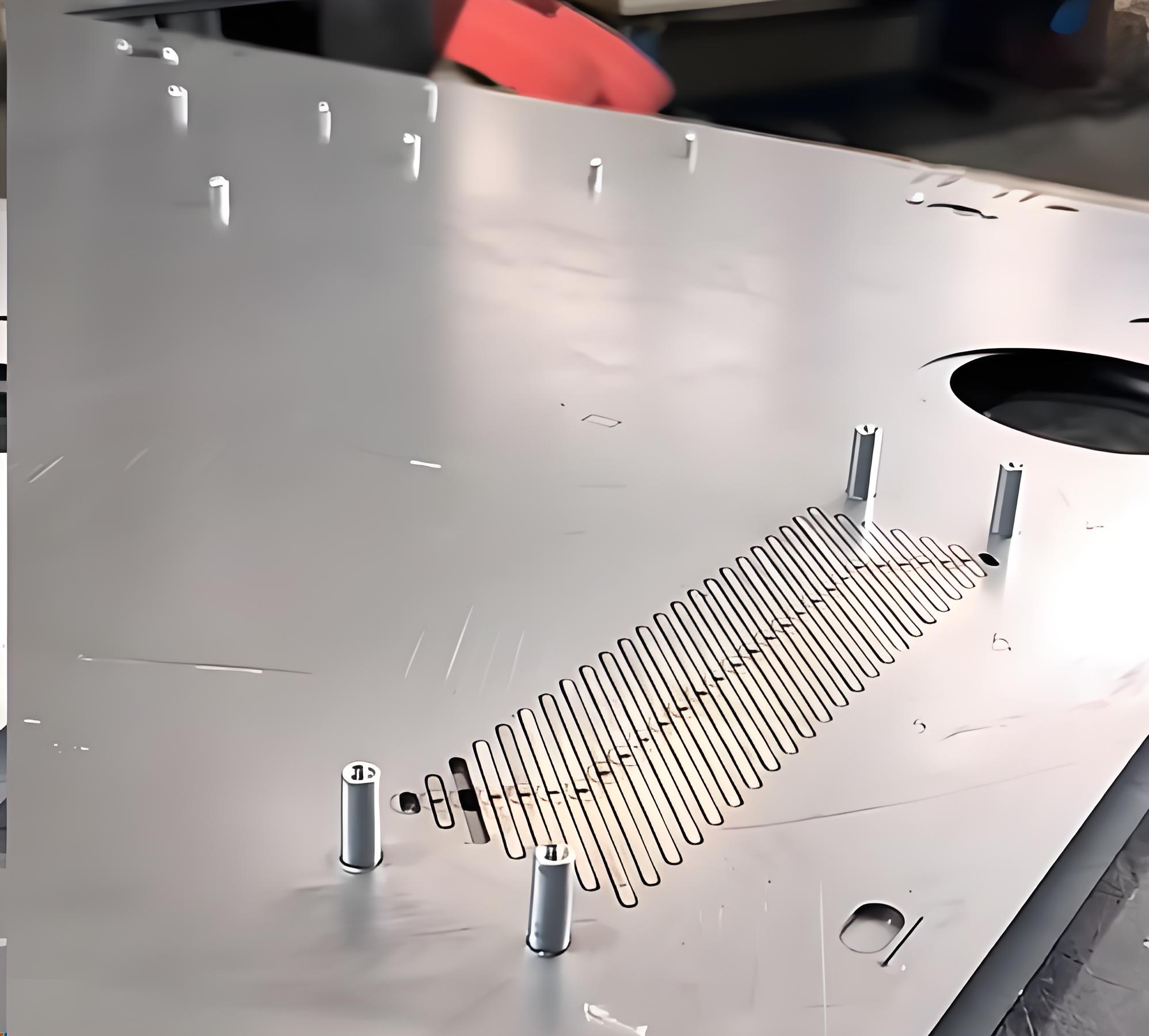

4. Working Principle

Clinch studs rely on cold-forming technology. When pressed into a pre-punched or drilled hole in a metal sheet (typically 0.5–6 mm thick), the clinch ring displaces the host material. This creates a mechanical interlock, embedding the stud permanently into the sheet. The knurled head prevents rotation, while the threaded shaft remains accessible for assembly.

5. Applications

Clinch studs are widely used in industries requiring secure, low-profile fastening:

Electronics: Mounting PCBs, heat sinks, or chassis components in devices.

Automotive: Attaching panels, brackets, or wiring harnesses.

HVAC Systems: Securing ductwork or filters.

Furniture and Appliances: Assembling sheet metal cabinets or frames.

6. Installation Method

Tools Required: Hydraulic press, arbor press, or specialized clinching tool; installation punch/die set.

Step-by-Step Process:

Prepare the Host Material:

Drill or punch a hole matching the stud’s recommended diameter (e.g., 3.3 mm for an M3 stud).

Ensure hole edges are deburred to prevent installation issues.

Position the Stud:

Apply Pressure:

Align the installation tool’s punch with the stud head.

Apply steady, axial pressure (typically 2–10 kN, depending on stud size/material).

The clinch ring deforms the host material, creating a flush, interlocked joint.

Inspect the Installation:

7. Key Advantages

Eliminates the need for welding, nuts, or backside access.

Maintains material integrity by avoiding heat distortion.

Reduces assembly time and labor costs.

8. Common Mistakes to Avoid

Incorrect Hole Size: Oversized holes prevent proper material displacement; undersized holes risk cracking.

Misalignment: Angled pressure can damage threads or weaken the joint.

Insufficient Force: Incomplete deformation reduces holding strength.

Conclusion

Clinch studs offer a robust, efficient solution for creating threaded points in thin materials. By selecting the appropriate material, surface treatment, and installation technique, engineers can achieve durable, high-performance assemblies in automotive, electronics, and industrial applications. Proper training and adherence to manufacturer specifications are critical to maximizing their benefits.