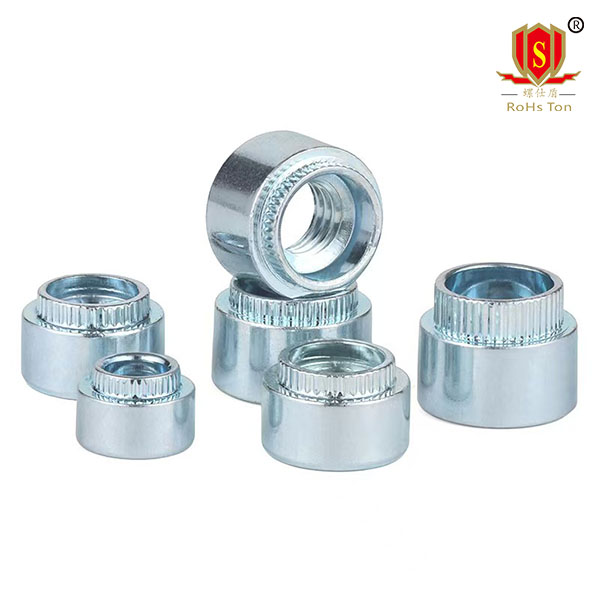

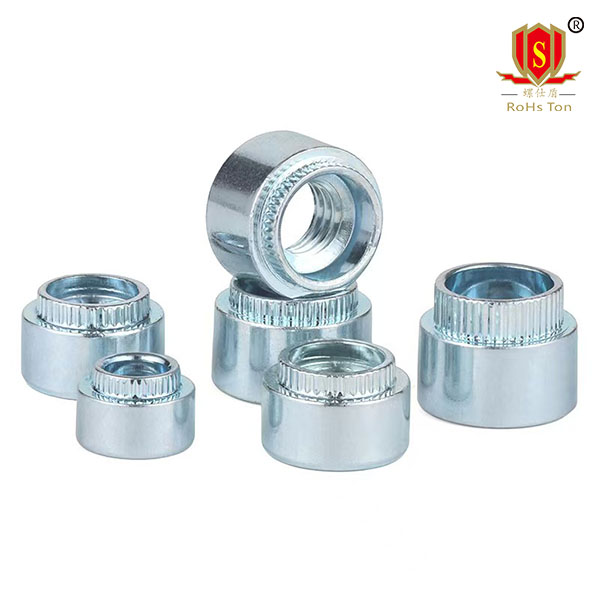

Rose riveting nuts are specialized fasteners designed for providing secure threaded connections in thin or soft materials, where traditional tapping or welding is impractical. They are widely used in industries such as automotive, construction, electronics, and machinery. This article provides an overview of their materials, surface treatments, classifications, working principles, usage methods, and application scenarios.

1. Materials

Rose riveting nuts are typically made from materials that balance strength, durability, and weight considerations. Common materials include:

· Carbon Steel: Offers high tensile strength and affordability, suitable for general applications.

· Stainless Steel: Corrosion-resistant and durable, ideal for harsh environments or outdoor use.

2. Surface Treatments

Surface treatments enhance the durability, corrosion resistance, and aesthetic qualities of rose riveting nuts. Common treatments include:

· Zinc Plating: Provides corrosion resistance and a clean appearance.

· Nickel Plating: Offers superior resistance to wear and corrosion.

· Phosphating: Improves surface adhesion for paint or coatings and offers basic corrosion resistance.

· Passivation: Used for stainless steel nuts to enhance their natural corrosion resistance.

3. Classification

Rose riveting nuts can be categorized based on various factors:

1.Shape: Cylindrical/Hexagonal

2.Thread Type:

Metric threads/Unified threads (imperial)

4. Working Principle

The principle of a rose riveting nut involves expansion and locking:

1. The nut is inserted into a pre-drilled hole in the base material.

2. A specialized tool squeezes the Rose Riveting Nut, causing the unthreaded section of the nut to expand outward.

3. The expanded section tightly grips the material, providing a secure and permanent threaded connection.

This design ensures reliable fastening even in thin or delicate materials that cannot support standard threads.

5. Usage Method

Using rose riveting nuts involves the following steps:

1. Hole Preparation: Drill a chamfered hole in the base material with a diameter matching the nut specifications.

2. Tool Setup: Attach the rose rivet nut to the installation tool.

3. Installation: Insert the nut into the hole and activate the machine to expand and secure the nut.

4. Thread Connection: After installation, screws or bolts can be threaded into the nut for fastening.

6. Application Scenarios

Rose riveting nuts find applications across various industries due to their versatility and ease of use:

1.Automotive Industry

Securing components to thin car panels, such as seats, door frames, and chassis parts.

Providing strong threads in lightweight materials like aluminum.

2.Construction

Fastening railings, frames, or brackets to metal structures.

Used in curtain walls and building facades.

3.Electronics and Appliances

Mounting circuit boards, fans, or heat sinks to thin enclosures.

Providing strong connections in plastic or sheet metal casings.

4.Machinery

Used in assembling and repairing industrial equipment.

Securing components to thin-walled parts of machines.

5.Aerospace and Marine

Lightweight and corrosion-resistant versions are used in aircraft and ships.

Ideal for joining lightweight materials like composites or thin metals.

6.Furniture and DIY Projects

Fastening wooden or metal frames without compromising structural integrity.

Popular for retrofitting or modifying existing structures.

Conclusion

Rose riveting nuts are indispensable fasteners that provide strong, reliable, and durable threaded connections across a wide range of materials and industries. Their variety in materials, surface treatments, and designs allows them to meet specific application requirements, from high-strength automotive uses to lightweight aerospace projects. Proper selection and installation of rose riveting nuts ensure efficient assembly and long-lasting connections, making them a cornerstone of modern manufacturing and engineering.